Woodworking Tools for Craftsmen

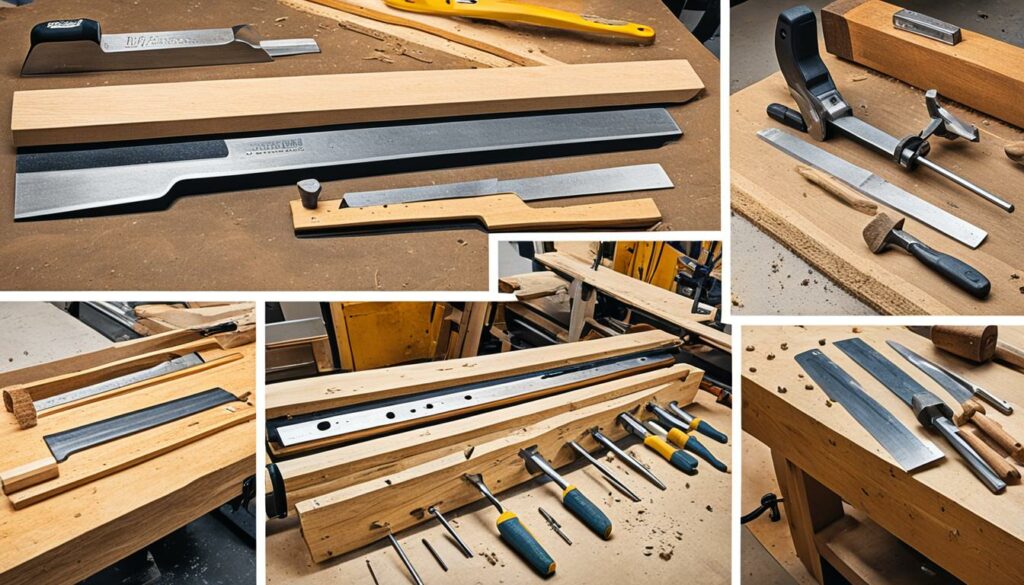

As a professional woodworker or craftsman, having the right tools is crucial to ensure the quality and efficiency of your work. In this comprehensive list, I have curated the best woodworking tools that every craftsman should have in their arsenal. From basic hand tools to power tools, this list covers everything you need to tackle any woodworking project.

Whether you’re a beginner or an experienced woodworker, these tools will help you achieve professional results. Let’s dive into the world of carpentry and discover the essential tools that every craftsman should have.

👉 Check out the Collection of Amazing Woodworking Plans

Key Takeaways:

✔️ Having the right woodworking tools is crucial for professional woodworkers or craftsmen.

✔️ A comprehensive list of essential woodworking tools can help ensure the quality and efficiency of your work.

✔️ From basic hand tools to power tools, a well-equipped toolbox is essential for tackling woodworking projects of any scale.

✔️ Choosing high-quality tools will contribute to achieving professional-grade results.

✔️ Investing in safety tools and gear is essential for creating a secure woodworking environment.

Touch of Basics: Fundamental Woodworking Tools

In this section, we will explore the fundamental woodworking tools that form the basis of every craftsman’s toolkit. These tools are essential for accurate measurements, marking, and ensuring proper alignment in woodworking plans.

The Craftsman’s Scribe: Pencils and Marking Tools

When it comes to woodworking, precision is key. Pencils and marking tools play a crucial role in creating precise outlines and measurements. Whether it’s marking dimensions, drawing lines for cutting, or creating intricate designs, these tools allow craftsmen to achieve accuracy in their woodworking projects. Investing in high-quality pencils, marking knives, and marking gauges will ensure that your measurements are spot on and your woodworking projects are flawless.

Measuring Mastery: Flexometers and Measuring Tapes

Accurate measurements are the foundation of every woodworking project. Flexometers and measuring tapes are versatile tools that allow craftsmen to measure various dimensions with ease. With their flexible bodies and clear markings, these tools enable precise measurements for both straight and curved surfaces. By choosing reliable and durable flexometers and measuring tapes, craftsmen can ensure accuracy in their woodworking projects, resulting in perfectly fitted pieces and seamless joinery.

Squaring Up: The Importance of Bevels and Squares

Angles and squareness are critical in carpentry work. Bevels and squares help craftsmen achieve precise angles and ensure squareness in their woodworking projects. Bevels allow for accurate angle measurements and can be adjusted to different angles, making them essential for creating beveled edges, miter joints, and angled cuts. Squares, on the other hand, are indispensable for checking the squareness of corners, marking perpendicular lines, and ensuring accuracy in joinery. By using reliable bevels and squares, craftsmen can achieve perfectly aligned and square woodworking pieces.

Holding Everything Together: Clamps and Vises

Clamps and vises are indispensable tools in woodworking, allowing craftsmen to securely hold and manipulate their workpieces. These tools provide stability and ensure precision in carpentry projects, making them essential for any craftsman’s workshop.

In this section, I will delve into the different types of clamps and vises available, including bar clamps, C-clamps, pipe clamps, and bench vises. By understanding the applications and features of each type, craftsmen can choose the right tool for specific woodworking tasks.

“Clamps and vises play a vital role in maintaining the stability and accuracy of woodworking projects, allowing craftsmen to focus on the craftsmanship without worrying about movement or slippage of workpieces.”

Bar clamps are versatile and can hold large or irregularly shaped workpieces securely. They consist of a bar that slides through a fixed or adjustable head, providing a wide range of clamping widths. This type of clamp is ideal for gluing and assembling projects.

C-clamps, also known as G-clamps, are shaped like the letter “C” and are commonly used for woodworking and metalworking. They are suitable for projects that require moderate clamping pressure and can be easily adjusted using a threaded screw mechanism.

🏆 Choose the Best Woodworking Plans for Craftsmen.

Pipe clamps are designed with a length of pipe that acts as the clamping mechanism. They provide a large clamping capacity and are suitable for projects that require a high clamping pressure. Pipe clamps are commonly used for edge gluing and panel assembly.

Bench vises are fixed to a workbench or table and provide a stable and secure clamping solution. They are commonly used for tasks that require both hands, such as sawing, planing, and chiseling. Bench vises come in various sizes and configurations, including front vises, end vises, and combination vises.

By utilizing the different types of clamps and vises, craftsmen can ensure precise and controlled woodworking, resulting in high-quality finished products.

| Clamp | Features | Applications |

|---|---|---|

| Bar Clamps | Versatile, adjustable, wide clamping width | Gluing, assembling |

| C-Clamps | Adjustable, moderate clamping pressure | Woodworking, metalworking |

| Pipe Clamps | Large clamping capacity, high clamping pressure | Edge gluing, panel assembly |

| Bench Vises | Fixed to workbench, stable and secure clamping | Sawing, planing, chiseling |

By understanding the applications and features of different clamps and vises, craftsmen can select the right tool for their woodworking projects and ensure precise and secure clamping, resulting in professional-level craftsmanship.

Cutting Edge: Saws and Blades for Woodworking

Saws and blades are crucial tools for cutting wood and other materials in woodworking projects. As a craftsman, choosing the right saw and blade is essential for achieving precise and clean cuts. In this section, we will explore the different types of saws available and their specific applications. We will also delve into the importance of selecting the appropriate blade for different cutting techniques and materials.

Choosing the Right Saw for Your Material

When it comes to choosing the right saw for your woodworking projects, it’s important to consider the material you will be cutting. Different types of saws are designed to excel in specific applications. Here are a few commonly used saws:

- Circular Saws: Ideal for making long, straight cuts in various materials, including wood, plywood, and plastic.

- Jigsaws: Best suited for making intricate curved cuts and plunge cuts.

- Hand Saws: Traditional hand-powered saws that are versatile and suitable for various cutting tasks.

By understanding the capabilities and limitations of each saw, you can select the appropriate tool for your specific material and cutting needs. This will ensure cleaner cuts and minimize the risk of damaging your workpiece.

Blade Selection: A Cut Above the Rest

Once you have chosen the right saw for your woodworking project, selecting the correct blade is equally important. The blade’s design, teeth per inch (TPI), and tooth configuration can greatly influence the performance and quality of your cuts. Here are some factors to consider:

- Tooth Count: Higher tooth counts provide smoother cuts, while lower tooth counts are more suitable for aggressive, rough cuts.

- Tooth Configuration: Blades with different tooth configurations, such as rip-cut, crosscut, and combination blades, are designed for specific cutting tasks and produce different results.

- Blade Material: The type of material the blade is made of affects its durability and performance. For example, carbide-tipped blades are known for their long-lasting sharpness and suitability for cutting hardwoods.

By understanding the nuances of blade selection, you can achieve cleaner and more precise cuts, resulting in a professional finish to your woodworking projects.

| Blade Type | Common Uses |

|---|---|

| Rip-Cut Blades | Ideal for cutting boards along the grain. |

| Crosscut Blades | Great for cutting across the grain, producing smoother edges. |

| Combination Blades | Versatile blades that can handle both rip-cutting and crosscutting tasks. |

Table: Common Blade Types and Their Uses

By selecting the right saw and blade for your woodworking projects, you can achieve precise and clean cuts, enhancing the quality of your work. Understanding the applications and features of different saws and blades allows craftsmen to unleash their creativity and bring their woodworking visions to life.

The Striking Force: Hammers and Mallets

Hammers and mallets are essential tools in woodworking, providing the striking force needed for driving nails, shaping wood, and more. As a craftsman, it’s crucial to have the right hammer or mallet for each task. Let’s explore the different types of hammers and mallets available and their specific applications in carpentry.

1. Claw Hammers: This versatile hammer features a curved claw on one side, which is ideal for removing nails. The flat face of the hammer is used for pounding and driving nails into wood.

2. Ball Peen Hammers: These hammers have a rounded, peen-shaped head on one side and a flat face on the other. They are commonly used in metalworking but can also be useful for shaping and forging metal components in woodworking projects.

3. Rubber Mallets: Unlike traditional hammers, rubber mallets have a soft rubber head that is less likely to damage delicate wood surfaces. They are used for assembling or disassembling woodworking joints and for other tasks that require light striking force.

When selecting a hammer or mallet, consider factors such as weight, handle grip, and the material you’ll be working with. A well-chosen tool will ensure precise and controlled strikes, making your woodworking projects a success.

Carving to Perfection: Chisels, Gouges, and Hand Tools

Chisels, gouges, and other hand tools are essential for carving, shaping, and detailing wood in woodworking projects. These tools allow craftsmen to achieve intricate and precise details, elevating their woodworking projects to new levels of craftsmanship. In this section, we will explore the different types of chisels and gouges, including bench chisels, mortise chisels, and carving gouges, and their specific uses in woodworking.

Woodcarving Essentials: Chisels and Their Uses

Chisels are indispensable tools for woodcarving and come in various shapes and sizes, each designed for specific tasks. Bench chisels are versatile and essential for general-purpose woodworking. They are commonly used for paring, chopping, and creating clean, straight cuts. Mortise chisels, on the other hand, are specifically designed for cutting deep, rectangular holes or mortises. Their robust construction allows them to withstand the force of mallet blows, making them ideal for heavy-duty tasks.

Carving gouges have curved cutting edges, making them perfect for shaping intricate curves, concave surfaces, and creating decorative patterns on wood. They come in different sweeps or curve profiles, allowing craftsmen to create a variety of designs and contours. From shallow gouges for fine details to deep gouges for significant material removal, woodcarvers rely on gouges to add depth, dimension, and artistic flair to their work.

The Functionality of Gouges in Detailed Work

Gouges excel at detailed work, allowing craftsmen to create intricate designs and smooth transitions in their woodworking projects. The curved cutting edge of gouges enables woodcarvers to shape concave surfaces, such as bowls or decorative moldings, with precision and control. They are also effective for creating texture and adding visual interest, as the curved shape of the gouge’s bevel produces unique patterns in the wood grain.

Woodcarvers can use gouges to sculpt figures, carve reliefs, and create intricate motifs. By mastering the art of using gouges, craftsmen can unleash their creativity and transform simple blocks of wood into stunning works of art. From delicate details to bold, sweeping curves, the versatility of gouges allows woodworkers to achieve the desired effects and express their artistic vision.

Shear Precision: Scissors and Cutting Tools

Scissors and cutting tools are indispensable when it comes to achieving precision in woodworking. These tools allow craftsmen to make accurate and clean cuts in various materials, ensuring the desired outcome of their projects. In this section, we will explore the different types of scissors and cutting tools that are ideal for woodworking tasks.

One essential cutting tool in any craftsman’s toolkit is the utility knife. With its sharp and replaceable blades, the utility knife is perfect for scoring and cutting through different materials, such as wood, plastic, and fabric. Its versatility makes it a must-have for any woodworking project.

“The utility knife is a reliable companion in woodworking, allowing craftsmen to make precise cuts in various materials.”

Precision knives, also known as hobby knives, are another important tool for accurate cuts in woodworking. These knives have a slim and pointed blade that can be easily maneuvered to create intricate shapes and designs. Their versatility makes them suitable for tasks such as carving, shaping, and trimming wood.

Aviation snips, commonly used in metalworking, also have their place in woodworking. These specialized cutting tools are designed to cut through sheet metal, but they can also be handy for trimming thin pieces of wood and plastics. The unique design of aviation snips allows for clean and controlled cuts, making them useful for various woodworking applications.

When choosing the right cutting tool for specific tasks, it is essential to consider factors such as the material being cut, the type of cut needed, and the level of precision required. By using the appropriate cutting tool, craftsmen can ensure the quality and accuracy of their woodworking projects.

Scissors and cutting tools play a crucial role in achieving shear precision in woodworking. These versatile tools, such as utility knives, precision knives, and aviation snips, allow craftsmen to make clean and accurate cuts in various materials. By selecting the right cutting tool for each task, craftsmen can achieve the desired results in their woodworking projects.

Drilling Down: Hand Drills and Augers

In woodworking projects, drilling precise and clean holes is a crucial step. Hand drills and augers are essential tools that every craftsman should have in their toolkit. Let’s explore the different types of hand drills and augers, their specific applications in carpentry, and when to opt for battery-free drilling.

The Auger: An Old-School Tool with Modern Utility

The auger is a classic hand tool that has stood the test of time. It features a twisted shaft and a cutting head designed to bore through wood effortlessly. Augers are available in various sizes and styles, including straight shank augers, spiral augers, and screw-point augers. These tools are ideal for drilling deep holes, such as for dowel joints or plumbing installations.

Battery-Free Drilling: When to Use a Hand Drill

While power drills offer convenience and speed, there are situations where a hand drill is the better choice. Hand drills, such as eggbeater drills and brace and bit sets, provide more control and precision. They are perfect for small-scale projects, delicate materials, or situations where power may not be readily available. Additionally, hand drills are often quieter, which can be beneficial when working in noise-sensitive environments.

To achieve accurate drilling results, craftsmen must choose the right tool for each drilling task. Hand drills and augers provide the versatility and control required to tackle various woodworking projects. Whether it’s for creating joinery, installing hardware, or adding intricate details, these tools are indispensable in the carpenter’s arsenal.

Smoothing the Surface: Rasps and Files

Rasps and files are essential tools for achieving a smooth and immaculate finish on wood surfaces in your woodworking projects. Whether you’re working on intricate detailing or simply aiming to create a polished appearance, rasps and files have got you covered.

When it comes to rasps, there are various types available to suit different needs. Hand rasps, with their coarse teeth, are perfect for quickly removing material and shaping areas of the wood. On the other hand, needle files are ideal for fine detail work and refining tight spaces. Cabinet rasps, with their wider shape, are excellent for leveling and smoothing larger surfaces.

Files, on the other hand, come in handy for refining edges and achieving precise angles. Flat files are commonly used for removing rough edges and shaping flat surfaces, while half-round files are great for working on curved or concave areas. Additionally, round files are perfect for enlarging holes or creating a rounded profile.

When selecting the right rasp or file for your needs, consider the type and condition of the wood you’re working with, as well as the level of detail required. Coarser teeth are suitable for rough shaping, while finer teeth are more appropriate for smoothing and finishing. It’s also essential to consider the size and shape of the tool, ensuring it fits comfortably in your hand and provides the necessary control.

By utilizing rasps and files, you can take your woodworking projects to the next level, achieving a smooth and professional-looking finish that showcases your craftsmanship.

Safeguarding Craftsmanship: Safety Tools and Gear

Safety is paramount when it comes to woodworking, both for the craftsmen and their valuable workpieces. In this section, I will discuss the essential safety tools and protective equipment that every woodworker should have in their workshop. Investing in proper personal protective equipment (PPE) is crucial to prevent accidents and injuries. It is vital to wear safety glasses, gloves, and ear protection to safeguard against potential hazards.

Creating a safe working environment is equally important. Start by organizing your workspace to minimize clutter and ensure a clear working area. Regularly clean the workspace and keep it free from hazards such as dust and debris. Utilizing safety devices like dust collection systems can help maintain a clean and healthy working environment.

By prioritizing safety and adopting these safety tools and measures, woodworkers can create a secure and productive working environment, allowing them to focus on their craft and achieve exceptional results.

Woodworking Tools

In this section, we will explore the must-have tools for every woodworker, including both hand tools and power tools. Equipping your toolkit with the right tools is essential to tackle any woodworking challenge and achieve professional-level results.

Must-Have Tools for Every Woodworker

As a woodworker, there are certain tools that you simply cannot do without. These tools form the foundation of your woodworking journey and enable you to create beautiful and functional pieces. Here are some must-have tools:

- Table Saw: A versatile and powerful tool for making straight cuts, rips, and crosscuts.

- Router: Perfect for creating decorative edges, joinery, and intricate patterns in wood.

- Random Orbital Sander: Essential for achieving a smooth and flawless finish on your projects.

Expanding Your Toolkit: Beyond the Basics

Once you have acquired the essential tools, you can start expanding your toolkit to take your woodworking skills to the next level. Specialized tools can help you tackle more advanced projects and add unique details to your work. Here are some tools to consider:

- Dovetail Jigs: Simplify the process of creating strong and beautiful dovetail joints.

- Biscuit Joiners: Aid in creating perfectly aligned and strong biscuit joints.

- Scroll Saws: Allow for intricate and detailed curved cuts in wood.

By expanding your toolkit beyond the basics, you open up a world of possibilities and enhance your woodworking capabilities. These specialized tools will enable you to take on more challenging projects and achieve outstanding results.

Brand Matters: Top Carpenter Tool Brands Reviewed

The brand of the woodworking tools you choose can significantly impact the quality and performance of your work. In this section, we will review the top carpenter tool brands in the market and explore their reputations, product offerings, and key features. We will discuss leading brands such as Dewalt, Milwaukee, Bosch, and Makita, and examine the benefits and considerations of choosing a specific brand for your woodworking needs. By understanding the strengths and specialties of different brands, craftsmen can make informed decisions when selecting woodworking tools.

FAQ

Don’t miss the frequently asked questions:

Some fundamental woodworking tools every craftsman should have include measuring tools, clamps, saws, hammers, chisels, and hand drills.

Clamps and vises provide stability and ensure precision in woodworking by securely holding and manipulating workpieces.

Common types of saws used in woodworking include circular saws, jigsaws, and hand saws. Different types of blades are used for specific cuts and materials.

Essential hand tools for woodworking include hammers, chisels, gouges, rasps, files, scissors, and cutting tools for shaping, detailing, and smoothing wood surfaces.

Personal protective equipment (PPE), such as safety glasses, gloves, and ear protection, should be worn. Maintaining a safe working environment by organizing the workspace and using dust collection systems is also important.

What are some must-have tools for woodworkers?

Must-have tools for woodworkers include table saws, routers, random orbital sanders, and expandable tools like dovetail jigs and biscuit joiners for more advanced projects.

Which are some top carpenter tool brands to consider?

Some top carpenter tool brands include Dewalt, Milwaukee, Bosch, and Makita, known for their durability, quality, and performance.

Final Recommendations

Having the right woodworking tools is essential for craftsmen to achieve professional results in their woodworking projects. Throughout this article, we have explored the fundamental tools every craftsman should have, such as measuring tools, clamps, saws, hammers, chisels, and many more. These tools are the building blocks of successful woodworking, allowing craftsmen to create precise measurements, secure their workpieces, make accurate cuts, and add intricate details.

We have also discussed the importance of safety tools and gear in ensuring a secure woodworking environment. By investing in personal protective equipment such as safety glasses, gloves, and ear protection, craftsmen can safeguard themselves from potential accidents and injuries. Additionally, creating a safe working environment through proper organization and the use of safety devices like dust collection systems further enhances the overall safety of the workshop.

Furthermore, we have highlighted the significance of choosing the right brand when it comes to carpentry tools. Brands like Dewalt, Milwaukee, Bosch, and Makita have established themselves as industry leaders, offering tools known for their durability, quality, and performance. By selecting tools from reputable brands, craftsmen can ensure reliability and longevity in their woodworking endeavors.